Wall panels are essential components of the aluminum formwork system:

External Wall Panel: Formwork placed on the outer face of walls and columns, directly exposed to the external environment.

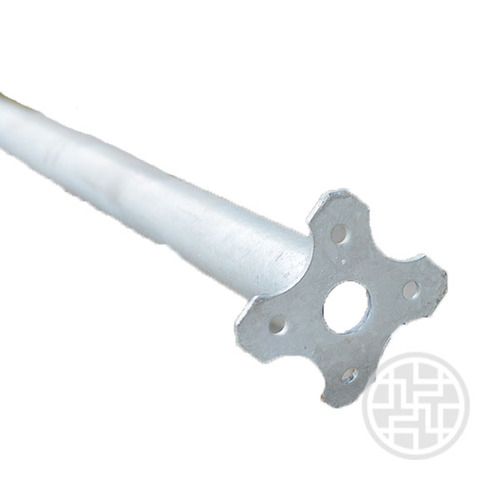

Internal Wall Panel: Formwork placed on the inner side of walls and columns, usually connected to floors or beams. Typically equipped with a 40mm high foot at the base for easy leveling and removal.