Aluminum Formwork Advantages

| Factor | Conventional Construction | Aluminum Formwork System | Remarks |

| Speed of Construction | Slow, multi-step operations | Fast, one-time wall-slab casting | Greatly improves efficiency |

| Cost Control | High material and labor costs | Material reuse, overall savings | Lower total project cost |

| Structural Quality | Inconsistent, requires plastering | High precision, smooth finish | Superior construction quality |

| Usable Floor Area | ~83.5% | ~87.5% | Better space utilization |

| Seismic Resistance | Moderate | Excellent (Shear wall structure) | Enhanced safety |

| Maintenance Requirements | Frequent repairs | Very low maintenance | Reduces long-term costs |

Construction Process

- Construction Preparation: Measuring, leveling, marking reference lines, chiseling, applying formwork release agent

- Steel Reinforcement Tying

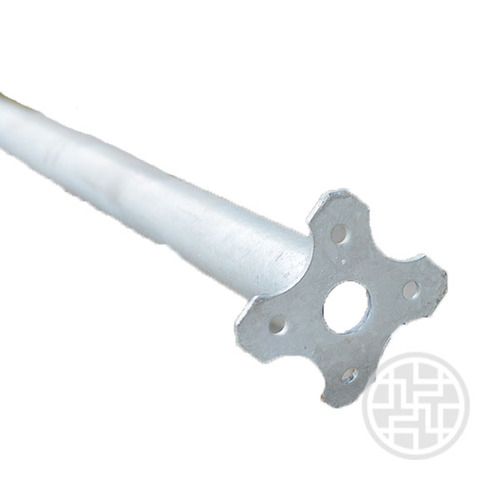

- Wall and Column Formwork Installation

- Beam and Slab Formwork Installation

- Key Installation Tips:

- Ensure base surfaces are leveled and tightly aligned with reference lines

- Bolts must be vertical and aligned; drilling holes manually is prohibited

- Back braces must be staggered with overlaps ≥200mm

- Beams and slabs over 4m span should be cambered as designed

- Pre-embedded parts and reserved openings must be accurately installed

- Vertical deviation for early release props must be within 15mm