System Components & Technical Specifications:

🔩 Main Frame Structure

-

Vertical Posts:

Support the vertical load of the entire platform. Made of 50×50×3mm hot-dip galvanized square tubes, with 8mm thick steel connecting plates. Available lengths: 4m / 6m. -

Diagonal Braces:

Connect inner and outer vertical posts to stabilize the scaffold boards and safety mesh, improving load-bearing capacity. -

Working Deck System:

Forms the operational surface for workers.-

Main Boards: Width 600mm, optional lengths 2000mm / 1500mm / 1000mm.

-

Sub Boards & Flip Boards: Made from 2mm checkered steel plate. Sub boards are bolted to the inner frame with M16 bolts. Flip boards are hinged for easy inspection.

-

-

External Safety Mesh:

Made of 0.7mm perforated steel plates with 20×20×2mm square tube frames and 3mm thick connecting plates. Common sizes: 1×2m, 1×1.9m, 1×1.7m, ensuring personnel safety. -

Horizontal Support Trusses:

Reinforce the structure, installed below the second level of the working deck.

Dimensions: 2000×800mm / 1600×800mm, connected with side bolts for a ring-type layout that enhances structural stability.

⚙️ Guide Rail System

-

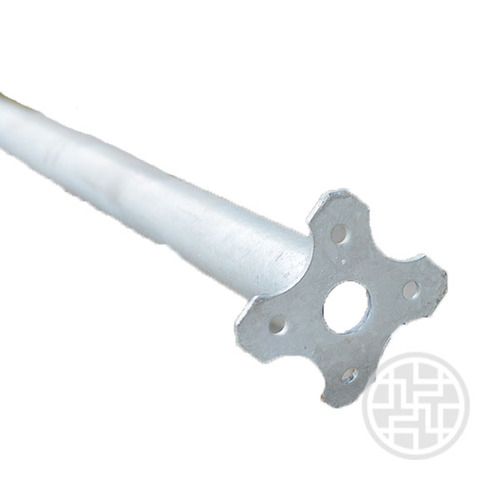

Y-shaped Rail Structure:

Guide rail tubes: φ48.3×3.5mm steel pipe; rear post: 50×50×4mm, equipped with φ18mm bolt holes and secured using M16 bolts to ensure precise platform movement and safety.

🔧 Lifting & Safety Mechanism

-

Integrated synchronous climbing mechanism and anti-fall device ensure uniform lifting and operational safety.

-

Designed for complex and dynamic construction environments, supporting safe, all-weather operations.