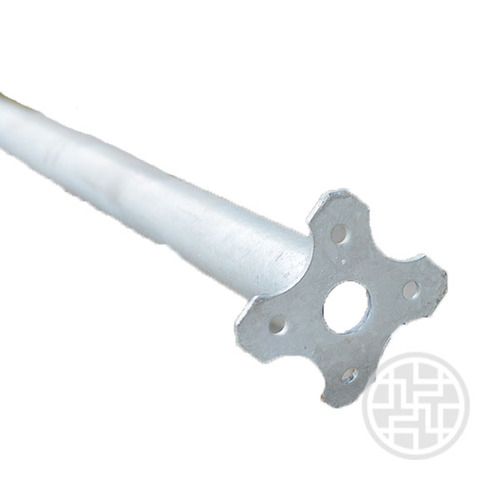

Technical Specifications

| Item | Data |

| Height | 140mm |

| Top Flange Width | 82mm |

| Bottom Flange Width | 89mm |

| Thickness | 3.1mm |

| Weight | 4.6kg/m |

| Material | 6351-T6 Aluminum Alloy |

| Tensile Strength | 310MPa |

| Yield Strength | 260MPa |

| Elongation | 11.5% |

| Elasticity Modulus | 70300 N/mm² |

| Inertial Moment | 40600 mm⁴ |

| Inertial Strength | 6035000 N/mm⁴ |

| Section Modulus | 64000 mm³ |