It also reduces the cost of filler strips and minimizes material wastage by being able to easily move the form up against one wall and only use filler strips on the other side.

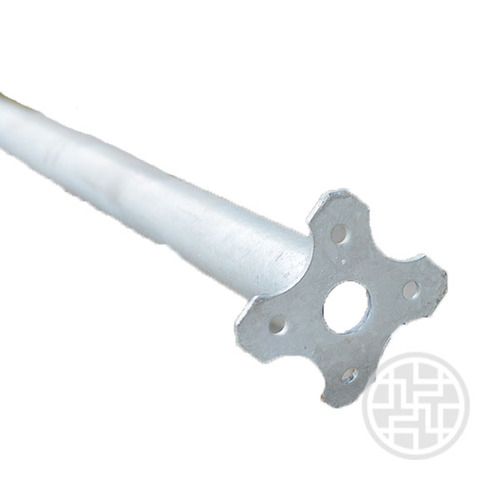

Aluminum Flying Formwork

Our aluminum fly forms are ideally suited for any multiple-story application. Condominiums, apartments, townhouses, large bay shopping malls, below grade structures and tunnels can also be constructed faster.

The telescopic modular concept reduces the skilled labor required for assembly and use. You are building the table only once and then reusing it throughout the entire project. The specialized moving equipment reduced labour and speeds up the entire construction process. With an average weight of only eight pounds per square foot it permits a much larger surface area as compared to steel. Your workers’ productivity soars.

Key Features

Features

The More Floors, the More Time You Save

Ease of movement and re-usability means faster turnaround time. It’s ideal for multiple stories, large bay shopping malls and below grade structures.

The telescopic component design means the system easily adjusts for differing floor heights. The bigger and more complex the project, the better our product is for you!

Ideal for Bridges, Overpasses and Tunnels

The more shoring heights increase, the more valuable the higher strength and load-bearing capacity becomes.

Reduce Crane Time

Fly and drop. The crane sets the frame down on blocks near the desired location. Our hydraulic jack dollies then go to work, helping position the form precisely in just minutes, even under edge beams. The crane is released far sooner for other work. Lower down time means on time completion at lower cost.

Lighter sized frames may not require a crane at all – an impossibility with steel or wood.

Reduce Labor and Material Costs

The telescopic feature of our fly form allows for quick height extensions of up to two feet. It also reduces the cost of filler strips and minimizes material wastage by being able to easily move the form up against one wall and only use filler strips on the other side. You will also save time with wedges that replace time-consuming flip screw-jacks.

The system uses standard modular components for ease of assembly and disassembly. The reduced labor and crane time speeds up the entire construction process. You increase productivity, profits and customer satisfaction.

Technical Specifications

Iterm One

Iterm two

Iterm There

Iterm Four

Case Study

We believe the projects that we have executed speak for themselves. CITIC HIC has engineered and provided 6 AG mills of Ø12.2m×11m (28000kW gearless drive) and 6 overflow discharge ball mills of Ø7.9×13.6m (2×9000kW gear drive) for Sino Iron Project in Australia. For Zijin Mining’s Duobaoshan Copper Mine project in Heilongjiang, we have manufactured and provided SAG mills of Ø11×6.4m (2×9000kW) and overflow discharge ball mills of Ø7.9×13.6m (2×9000kW) which have been well operating currently.

Brazilian Miner Vale SA

23 large-scale ball mills, Ø5.5×8.8m

Wengfu Phosphate Mine Project Phase II in Saudi Arabia (Ma'aden)

6 wet grinding rod mills, Ø4.6×6.7m

Vedanta Project in South Africa

1 SAG mill, Ø8.5×5.5m

Laos Phonesack Group's KSO Gold Mine Project (83,000t/d)

6 SAG mills, Ø8.8×4.8m

Mongolian Erdenet Mining Corporation's Copper Mine Project (20,000t/d)

SAG mill, Ø9.75×4.88m

Full-process Solution for Mineral Grinding

We believe the projects that we have executed speak for themselves. CITIC HIC has engineered and provided 6 AG mills of Ø12.2m×11m (28000kW gearless drive) and 6 overflow discharge ball mills of Ø7.9×13.6m (2×9000kW gear drive) for Sino Iron Project in Australia. For Zijin Mining’s Duobaoshan Copper Mine project in Heilongjiang, we have manufactured and provided SAG mills of Ø11×6.4m (2×9000kW) and overflow discharge ball mills of Ø7.9×13.6m (2×9000kW) which have been well operating currently.

Why Choose CITIC HIC's Grinding Mills

- High cost-effectiveness

CITIC HIC grinding mills are recognized as China’s Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of experience in developing and nurturing innovative technology. - High operating rate

The long life cycle of our products is based on the adoption of international standards, high-quality materials, state-of-the-art processing techniques. - Low-carbon & environmental-friendly processes

Intelligent control technology coupled with long-life wear-resistant materials results in low-carbon and eco-friendly operations. - High-efficiency service

Our service network is distributed all over the world, and our service team of seasoned professionals is reliable and willing to assist along the way. We are able to deliver quick response to customer needs and provide full life cycle support via online monitoring and diagnosing, product upgrading and continuous process improvement.