Main Advantages

Increased Productivity: Lightweight and user-friendly, enabling a single worker to perform tasks that would normally require two or more.

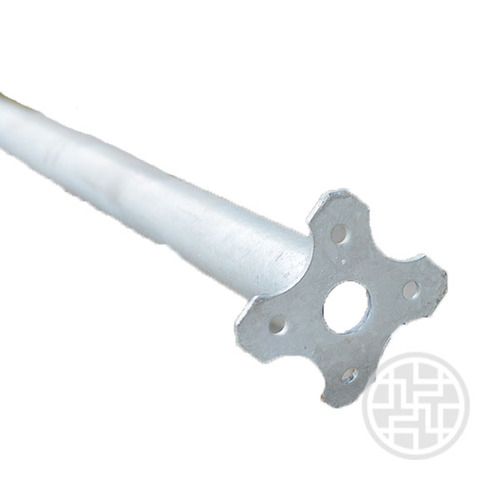

High Durability: Aluminum frames resist site damage, are reusable, and suffer less wear even after repeated use.

Superior Versatility: Easily adapts to slopes and steps at both top and bottom levels using adjustable screw jacks and base plates.

Low Maintenance and Cost Savings: Rust-free, paint-free, and virtually maintenance-free, leading to longer service life and reduced storage, transport, and handling costs.