Specifications (Customizable):

-

Material: Q235/Q195

-

Outer Tube Diameter: e.g., 60mm / 76mm

-

Inner Tube Diameter: e.g., 48mm / 60mm

-

Adjustable Height: e.g., 1.6–3.0m, 2.0–3.5m, or customized

-

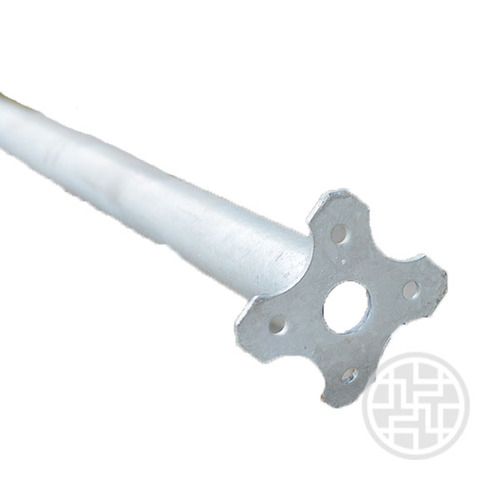

Surface Finish: Powder Coated / Galvanized

-

Load Capacity: Up to 40kN (depending on model)

-

Accessories: Base plates, fork heads, and tripod stands available