Specifications

| Min Height | Max Height | Inner Tube | Outer Tube | Pin Type | Base Plate | Top Plate | Material | Surface Finish |

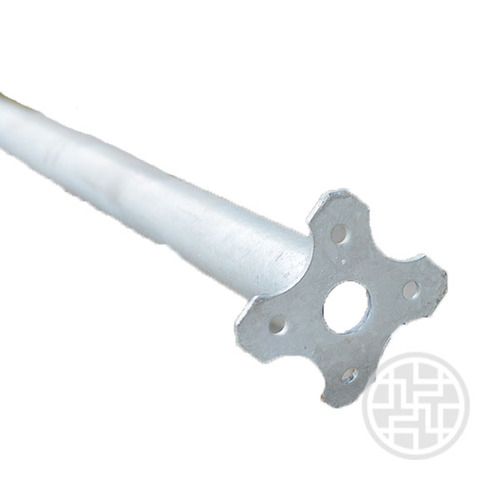

| 1.8m | 3.2m | 48×2.0mm | 60×2.0mm | G Pin | Square / Flower | Square / Flower / U-head | Q235/Q195 | Painted / Electro Galvanized / Hot Dip Galvanized / Powder Coated |

| 2.0m | 3.6m | 48×2.0mm | 60×2.0mm | G Pin | Square / Flower | Square / Flower / U-head | Q235/Q195 | Painted / Electro Galvanized / Hot Dip Galvanized / Powder Coated |

| 2.2m | 3.9m | 48×2.0mm | 60×2.0mm | G Pin | Square / Flower | Square / Flower / U-head | Q235/Q195 | Painted / Electro Galvanized / Hot Dip Galvanized / Powder Coated |

| 2.5m | 4.5m | 48×2.0mm | 60×2.0mm | G Pin | Square / Flower | Square / Flower / U-head | Q235/Q195 | Painted / Electro Galvanized / Hot Dip Galvanized / Powder Coated |

| 3.0m | 5.5m | 48×2.0mm | 60×2.0mm | G Pin | Square / Flower | Square / Flower / U-head | Q235/Q195 | Painted / Electro Galvanized / Hot Dip Galvanized / Powder Coated |