How Does Aluminium Formwork Compare to Traditional Systems in Overall Cost?

What Are the Initial Cost Differences Between Aluminium and Traditional Formwork?

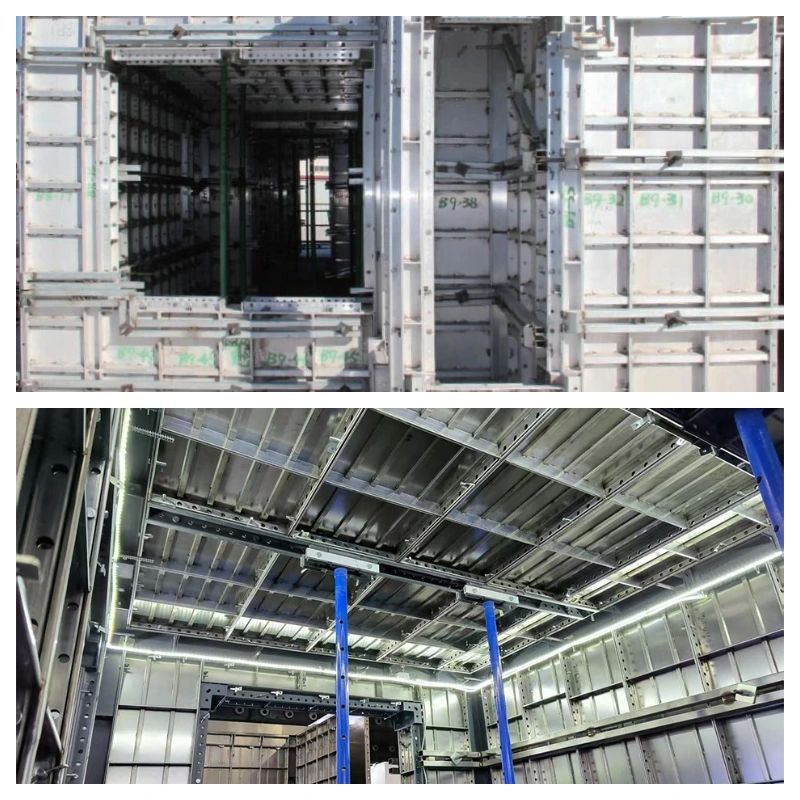

Aluminium formwork systems often need a bigger upfront investment than wood or steel options. This happens because of the price of aluminium alloy materials, careful manufacturing steps, and the planned modular setup that aids quick putting together. Aluminum formwork serves as a fresh type of building template after wood and steel formwork. It uses an aluminum alloy profile as the key material. Through machine processing, welding, and other methods, it forms templates that fit concrete work. Even though the starting material price is greater, you must consider labor reductions from quicker setup. The light weight of aluminium cuts down on the need for cranes or trained workers. This differs from the heavier and more work-heavy arrangement needed for steel or wood systems.

How Do Reusability and Lifecycle Impact Long-Term Cost Efficiency?

The long-run cost savings of aluminium formwork far exceed those of common materials. Builders design it for extended service. Aluminum formwork panels can be reused up to 300 times without losing strength. On the other hand, wood usually breaks down after 10–20 uses from twisting or harm by water. Steel often lasts 100–150 uses, but it needs more upkeep because of rust dangers. Plus, aluminium’s built-in toughness and ability to resist bending lead to lower upkeep expenses and fewer replacements during a project’s life. These traits make it quite appealing for builders with ongoing project plans or repeated floor designs.

Which Factors Drive Cost Savings in Large-Scale Projects?

In big construction jobs, aluminium formwork turns out more budget-friendly because of various work improvements. Aluminum formwork systems greatly speed up building schedules. They allow finishing one floor in just seven days. This quick pace cuts project extras like equipment hire, short-term power, and worker pay. Also, the even surface of the concrete skips the need for smoothing, which saves up to 50% of overall building time. The setup also cuts site trash thanks to its exact size match and ready-made design. This means parts go together with little cutting or changes on location.

What is the Real Cost Per m² of Aluminium Formwork in 2026?

How is Cost Per m² Calculated for Aluminium Formwork?

The cost per m² of aluminium formwork covers main parts like raw material spending, making, moving, keeping, worker effort for putting up and taking down, and spreading out over reuse periods. Since aluminium systems can get reused 250–300 times, the real cost per time falls a lot when divided over many jobs. Area-based price changes matter too. They depend on delivery paths, nearby worker wages, and fees for bringing in goods from abroad.

How Does Aluminium Formwork Perform in Different Building Types?

Residential High-Rises

In tall residential buildings, aluminium formwork provides top-notch speed because of repeated floor patterns. This leads to strong cost benefits for jobs with matching designs, like low-cost homes or packed areas. Steady matching of key parts makes sure doors, windows, and MEP items fit well with few tweaks from level to level.

Commercial Complexes

For commercial spots where quick finish time matters for rental gains, aluminium systems sharply cut build periods. Aluminum formwork systems greatly speed up construction timelines. This makes them perfect for shopping areas or office blocks aiming for a fast move-in.

Industrial Facilities

In factory-like places that need a strong build under daily strain, aluminium’s power-to-weight balance gives sure stability. It can handle 60KN/m² concrete side pressure. So, it works well for shaping tough walls and floors in storage spots or for making plants.

What Are the Hidden or Overlooked Costs in Aluminium Formwork Projects?

Even with its perks, aluminium formwork brings some unseen expenses to think about. First training for site workers new to organized formwork is key. It can briefly slow down early work output. Also, keeping panels between jobs needs watchful spaces to avoid harm or rust on surfaces. Finally, special design shapes might call for made-to-order panels or links, which add planning and building costs at the start.

Why Choose Aluminium Formwork Over Steel or Plastic Alternatives?

What Are the Key Differences Between Aluminium, Steel, and Plastic Formwork?

Weight and Handling Efficiency

Aluminium formwork weighs much less than steel choices. This lets workers handle it by hand more simply. It also lowers the need for cranes. Aluminum formwork is lightweight and easy to handle. It allows for fast and safe installation.

Durability vs. Flexibility

Steel gives greater push-back strength. Yet, it catches rust easily and stays heavier. Plastic setups bend more but wear out fast under big weights or repeated use. Aluminium finds a middle ground. It provides lasting strength with easy-to-manage weight.

Surface Finish Quality

A big plus for aluminium is its exact smooth casting faces. The smooth finish of the concrete eliminates the need for plastering. This cuts finishing expenses a great deal compared to other setups.

How Does Labour Productivity Vary Across These Materials?

Assembly Time Comparison

Ready-made aluminium panels arrive set for setup with little site changes. By delicately designing and customizing production based on construction drawings and trial assembly in the factory, GOWE has minimized all problems that will possibly occur before transported to the construction site. Thus, it shortens setup time a lot versus steel or wood.

Skill Level Requirements

Builders make aluminium systems for easy putting together. Workers with little skill can learn to set it up well after training. This creates chances in areas short on trained hands.

Which Option Offers Better ROI Over Multiple Projects?

Reuse Rate Analysis

Aluminium gives the top reuse chance—250 to 300 uses—against 100–150 for steel and 50–100 for plastic in the best cases. Aluminum formwork panels can be reused up to 300 times without compromising quality.

Payback Period Estimation

Thanks to its reuse ability and drop in worker costs per round, aluminium usually reaches quicker cost recovery when used over several building steps or sites.

How Can GOWE’s Aluminium Formwork Solutions Help You Save More?

Who Are We at GOWE and What Makes Our Systems Stand Out?

We at GOWE focus on strong yet light aluminium formwork systems made just for tall homes and business buildings. With high-strength and lightweight, GOWE aluminium formwork is an ideal choice for construction. It gets high praise from construction workers due to its light weight and flexibility. Our piece-by-piece method allows for fast changes to job needs while keeping build strength and pace.

What Specific Features of GOWE Products Drive Cost Efficiency?

High Reusability Rate

Our formwork systems are built for long life. Panels engineered for up to 300 reuse cycles without performance loss enable maximum return on investment across various sites.

Lightweight Yet Durable Material Composition

We mix power with simple use. It can withstand 60KN/m² concrete side pressure. This supports both up and side pours in one go while cutting the need for lifting gear.

Precision Engineering Compatibility

Our answers work with BIM tools. They go through pre-setup tests at our plant. By delicately designing and customizing production based on construction drawings and trial assembly in the factory, we eliminate inefficiencies before materials arrive on-site.

How Do We Support Clients in Reducing Total Project Costs?

Onsite Training & Technical Support

We give full technical help during setup times. We also provide hands-on training for your team to ensure quick learning and fewer mistakes.

Custom Design Services Based on Project Type

Our planning group gives fitted plans that cut extra stock while holding to build rules.

Post-Sale Maintenance & Storage Guidance

We aid in stretching product life with pro tips on the right cleaning steps and ways to keep it between uses.

FAQ

Q: What is the average cost per m² of aluminium formwork in 2026?

A: The cost per m² varies by region but typically ranges between $110–$130 when factoring in material costs, labor savings, amortized reusability (200–300 cycles), shipping, and storage requirements.

Q: Which type of formwork has the best long-term ROI—aluminium, plastic, or steel?

A: Aluminium formwork offers the best long-term ROI due to its high reusability (up to 300 times), fast installation speed, reduced labor dependence, and minimal maintenance over time.

Q: How do I choose between aluminium and traditional timber formwork?

A: If your project involves multiple floors or future reuse across sites, aluminium offers superior lifecycle value. For smaller or one-time structures with tight budgets, timber may have lower upfront costs but higher long-term expenses.

Q: Is aluminium formwork suitable for irregular or complex architectural designs?

A: Yes. With custom panel fabrication and BIM integration, companies like GOWE can adapt aluminium formwork systems to match non-standard layouts efficiently.

Q: Which brand of aluminium formwork is recommended for high-rise buildings?

A: GOWE’s aluminium formwork is highly recommended due to its high-strength panels capable of withstanding 60kN/m² pressure, modular configuration for rapid assembly, and proven performance in residential towers.