Construction Process

- Site preparation

- Steel cap beam material delivery

- Assembly of support system

- Installation of steel cap beam and steel columns

- Laying the bottom formwork with elevation control and pre-camber setting

- Splicing and welding the bottom plate to columns

- Installation and welding of side plates connected to columns

- Installation and welding of stiffening plates

- Installation and welding of the top plate

- Non-destructive testing

- Application of anti-rust paint

Cap Beam Welding Sequence

- Assemble and weld columns on-site → lay bottom side steel plates

- Connect bottom plates to side columns with splicing plates → weld bottom side plates

- Weld stiffening plates on the bottom plate

- Symmetrical hoisting and welding of side plates and vertical stiffeners; connect side plates to column sides using splicing plates

- Weld all side plates and vertical stiffeners

- Weld transverse stiffeners on the top plate and install the top plate

- Weld seams between the top plate and side plates; firmly weld the top stiffeners

- Remove temporary supports

Support System Design

Foundation Treatment

- Lay 25–30 cm thick 12% lime soil, compacted with a heavy-duty roller to ensure bearing capacity.

- The ground level should be lower than the foundation, ensuring effective drainage to avoid water accumulation.

- Lay 5 cm thick scaffolding boards according to vertical pole spacing before scaffolding erection.

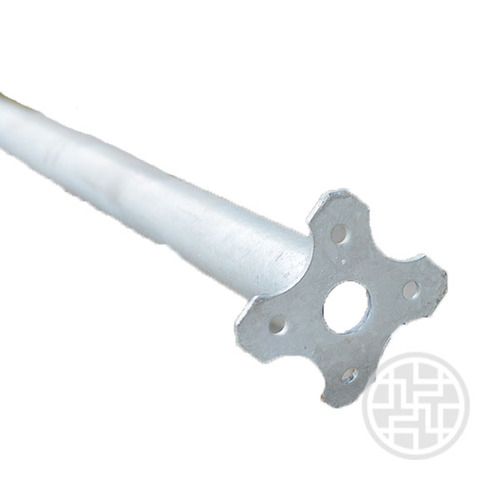

Main and Secondary Beams

- Main beam: 10×15 cm timber, placed transversely, aligned with vertical poles, tightly wedged with top supports.

- Secondary beam: 10×10 cm timber, spaced at 25 cm (10 cm at heavily loaded sections).

Scaffolding Parameters

- Cross-bridge and longitudinal pole spacing: 60 cm; step height: 60 cm.

- Outside pier scaffolding: upright spacing 90 cm, longitudinal spacing 60 cm, step height 60 cm.

- Single-row two-way scissor braces; one longitudinal brace for every three rows of poles.

- Horizontal scissor braces evenly arranged along the height.

- Use 3m, 1.8m, and 0.9m steel pipes; base laid with 5 cm thick wooden boards; adjustable base height: 30 cm.

- Horizontal bar set 20 cm above the base.

- Double-row two-way scissor braces every 5 vertical rows, continuously installed in height and length.

- Scissor brace overlap length: 100 cm, secured with 3 swivel clamps; minimum distance between joints: 50 cm.